2014

DSD GmbH invests in measurement technology

The Druckguss Service Deutschland GmbH is expanding its capabilities in the field of measurement technology by buying a FARO Laser Tracker Vantage. The new FARO Laser Tracker defined new standards in 3D-measurement technology in terms of accuracy and flexibility. Due to its ease of use the Laser Tracker is applicable versatile for different tasks in foundries and factories around the world.

Together with the FARO Arm Prime, the DSD-GmbH now has two of the latest measuring instruments. So extensive measurement concepts can be realized and documented.

DSD GmbH again demonstrates its innovative ability

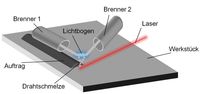

Industrial maturity almost reached - Successful completion of the KMU Innovation project "HoDopp"

To achieve improved quality and higher processing speeds in the process of welding on (building up) wearing surface and corrosion protection layers on large components (eg platens of die casting machines) was the aim of Druckguss Service Deutschland GmbH, the Laser Zentrum Hannover (LZH eV) and two industrial partners.

Read more … DSD GmbH again demonstrates its innovative ability

The welding certificate has been issued successfully.

On 18.08.2014 Druckguss Service Deutschland GmbH has been audited and successfully approved regarding the ability to manufacture steel structures acc. to EN 1090-2 Exc 3 (Execution Class 3).

Druckguss Service Deutschland GmbH is processing all steels of the material group 1.1 and 1.2 as well as stainless steels acc. to Z 30.3-5 of the general construction approval of the DIBt.

Read more … The welding certificate has been issued successfully.

Funding certificate handed over by Minister Meyer

On Tuesday 08/07/2014 the Minister of Economic Affairs Schleswig-Holstein Reinhard Meyer paid a visit to our company in Lübeck.

In the scope of the plant visit, the Minister handed over the funding certificate in the amount of 500,000 euros to our managing director Heribert Höhr. Hereby the Federal Land of Schleswig-Holstein supports the expansion of our premises in Lübeck / Schlutup - the construction of an additional hall in which the new 'Universal milling center' will find a home.

Read more … Funding certificate handed over by Minister Meyer

DSD GmbH invests in the future

Druckguss Service Deutschland GmbH is expanding its production capacity by a universal milling center!

maximum processing size: y = 6100 mm; x = 12000 mm; z = 1800-2000 mm

Round table size: 130 t SWL

A part of this investment is the establishment in Lübeck / Schlutup of a 900 m2 new production hall, which includes a 100-ton crane.

The extension secures the DSD-quality standard and offers to keep the well known flexibility regarding handling of spare parts and components in the field of service for die casting machines of all manufacturers.

In addition to that, the possibilities of contract manufacturing will expand especially for ...

New Borewelder-System

Since April, a new "internal circumferential build-up welding process" for mobile applications available. With only one set-up process three operations are possible.

PRE BORING - BUILD-UP WELDING - POST MACHINING

NORTEC

the trade fair for production in the north

Tue 21 to Fri 24 January 2014 in Hamburg

We are in Hall A1 at the stand A1.222. The focus is on the presentation of our capabilities in the field of mechanical manufacturing.