DSD UP TO DATE

Our NEW BOOM Truck is in action now!

Here you can see the relocation of an injection molding machine.

The BOOM Truck effortlessly lifts 50t!

Whenever overhead cranes are not sufficient and crane trucks cannot be used due to lack of space, the BOOM-TRUCK is the solution.

The dimensions of the BOOM Truck: L = 5.00 m / W = 2.15 m / H = 3.00 m.

Your team from DSD

DSD UP TO DATE

Welcome!

We welcome our new trainees!

In the area of precision mechanics, specializing in machining, we have a new addition in the form of Mr. Kilian Jazdzynski and Mr. Moses Mertz.

The field of mechanical engineering is growing with the addition of Mr. Tim Luca Langbehn.

We are looking forward to the future cooperation and a successful, instructive and fun training period.

We will also be looking for new trainees for the year 2023!

We are looking forward to every application

Your team from DSD

DSD UP TO DATE

Our DuoCast creates twice the amount of castings in the same time, with better quality!

Here is an interesting article about the Duocast in the trade magazine ''Giesserei''.

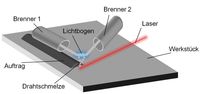

''The latest innovation from Druckguss Service Deutschland GmbH is DuoCast. With its patented series arrangement, it enables the operation

of two die casting molds on one casting machine''

Your team from DSD

DSD at GIFA 2019

GIFA 2019 - This has been our booth!

If you had not the possibility to visit us at the GIFA this year, we created this video for you. This is the chance to get an impression of our booth and the new innovation of the DuoCast.

Again we want to thank every visitor and employee who has made this successful exhibition possible.

If you need any further information about the new machine or other services of our company, please contact us.

Your team from DSD!

DSD at GIFA 2019

A successful week of exhibition has an end!

The GIFA 2019 and the connected presentation of our brand new DuoCast is over and we can take a very successful review with interesting talks on our booth.

We´re thankful for every visitor who has visited us last week and the interest you show for our company and our new machine.

Also we would like to thank every employee who has made this exhibition possible.

For more information about the machine please click the link below.

Your team from DSD!

DSD Interns

Support in different departements

In the term from 12/3/2018 to 23/3/2018 we have the pleasure to share our daily routine with five interns of our cooperation partner the Willy Brandt Schule in Schlutup.

These interns are supporting us in different departments. Two girls are placed in the office as an industrial manager, two boys are working in the drilling departement and the last girl supports the mechatronics.

The two dedicated interns of the office have written a small report about their first week in our company.

Your team of DSD

Review NORTEC 2018

Review NORTEC 2018

The manufactoring trade fair in Hamburg has gone and we can look back to an interesting and successful week with great conversations and discussions.

We want to thank everyone who visited us in Hamburg and we are looking forward for the next meeting of the manufactoring variety of Germany.

Your Team of DSD

Review EUROGUSS 2018

THANK YOU!

The team of Druckguss Service Deutschland GmbH is happy about the successful exhibition in Nuremberg. We had interesting conversations and also a great atmosphere at our booth.

We want to thank every companion, customer and visitor for visiting us at the EUROGUSS 2018, we hope to meet you again in 2020.

Your team of DSD

DSD at NORTEC 2018

Visit us!

We´re also a part of the manufacturing trade fair in the heart of Hamburg. If you want to get a closer view about our manufactoring variety, visit us at NORTEC 2018.

We look forward welcoming you at our booth 725 in hall A1.

Your team from DSD

DSD at EUROGUSS 2018

Visit us!

Two years has gone and it is time for the EUROGUSS again.

Be prepared for brand new innovations from the specilalists of DSD. In the period of the 16.01- till 18.01.2018 you can get in touch with the latest developments in the die casting sector.

We look forward welcoming you at our stand 740 in hall 7.

Your team from DSD

DSD trainees

Internship in Bristol? Do or don't

Our trainee Chris Heckmann is visiting Bristol in England at the moment for an internship. He will visit this small english city for three weeks and will get in touch with a foreign language and culture.

Your team from DSD

DSD at European Business Summit in Brussels

"Europe's largest networking platform where business and politics shape the future of Europe!"

DSD has been invited to speak at the "European Dialogue on Skills and Migration" in Brussels about the experience of integration of refugees in the workplace.

Your team from DSD

DSD - at METAFO in Tehran

This year we are exhibiting together with our partners at METAFO in Tehran.

The first two days are over and we are looking forward to the next days.

Your team from DSD

DSD - Review Euroguss 2016

It was an exhibition with interesting conversations and a great atmosphere. New contacts were made and one or the other voice can be associated with a face now. We were pleased about many old companions, who found their way to our stand and contributed so significantly to the success of this fair.

DSD - New York Times

With pride we can now announce that the article and the video made here at our company, is now online.

http://www.nytimes.com/2015/12/23/world/europe/migrants-refugees-germany.html?_r=0

DSD - Craft Is Intercultural

Several major magazines, including the "Frankfurter Allgemeine Zeitung" and the "New York Times" viewed our commitment to give refugees a perspective. In cooperation with the Chamber of Crafts, we are part of the project "Craft is intercultural". Click here for the articles in the online portals for your perusal:

DSD - UniForce 8

The commissioning of the SHW UniForce 8 is getting closer.

Meanwhile the imposing tower with its tool changer and the operator stand is installed. An official opening will take place in early November. Further information will follow.

DSD - mission 'new machinig center' starts

The first components for our new SHW-traveling column machine UniForce 8 were delivered and placed. The delivery of up to 50t heavy machinery parts was performed by heavy transport and was a first small test for the handling.

The overhead crane placed the components safely in the intended place and already demonstrated its added value for the DSD GmbH.

Your team of Druckguss Service Deutschland GmbH

DSD - Now it will be heavy!

The overhead crane for our new SHW-traveling column machine UniForce 8 was successfully approved. For this purpose weights of totally 125t were brought to Lübeck to check the overhead crane for our large machining center.

This "weight class" is necessary for the equipment of the traveling column machine with workpieces up to 100t piece weight, so that the listed workspace can be fully utilized:

X-axis - table / stand along: 12.000mm

Y-axis - vertical slide: 6.500mm

Z-axis - headstock cross by 1.900mm

W-axis: 2.500mm

DSD - Review GIFA 2015

It was an exhibition with interesting conversations and a great atmosphere. New contacts were made and one or the other voice can be associated with a face now. We were pleased about many old companions, who found their way to our stand and contributed so significantly to the success of this fair.

Our new booth concept has made us special among other exhibitors. The slogan "Holiday and regeneration for your die-casting machine" at the Baltic Sea was presented - beginning with the manufacture of spare parts up to an individual overhaul.

Half time at GIFA - Impressions!

Thank you for the many visitors and the interesting discussions at our booth in Hall 11. Here already some impressions from the first half of the International Foundry Trade Fair from Duesseldorf.

Furthermore, we wish our customers and business partners a successful trade fair.

Your team of Druckguss Service Deutschland

DSD GmbH image film

Discover the range of Druckguss Service Deutschland GmbH, a specialty mechanical engineering company from luebeck.

Your competent partner - not only for die casting machines!

Convice yourself! Now, our service is available in audio and video.

Click here to start the movie

Enjoy watching

Your Team of Druckguss Service Deutschland GmbH

DSD GmbH invests in measurement technology

The Druckguss Service Deutschland GmbH is expanding its capabilities in the field of measurement technology by buying a FARO Laser Tracker Vantage. The new FARO Laser Tracker defined new standards in 3D-measurement technology in terms of accuracy and flexibility. Due to its ease of use the Laser Tracker is applicable versatile for different tasks in foundries and factories around the world.

Together with the FARO Arm Prime, the DSD-GmbH now has two of the latest measuring instruments. So extensive measurement concepts can be realized and documented.

DSD GmbH again demonstrates its innovative ability

Industrial maturity almost reached - Successful completion of the KMU Innovation project "HoDopp"

To achieve improved quality and higher processing speeds in the process of welding on (building up) wearing surface and corrosion protection layers on large components (eg platens of die casting machines) was the aim of Druckguss Service Deutschland GmbH, the Laser Zentrum Hannover (LZH eV) and two industrial partners.

Read more … DSD GmbH again demonstrates its innovative ability

The welding certificate has been issued successfully.

On 18.08.2014 Druckguss Service Deutschland GmbH has been audited and successfully approved regarding the ability to manufacture steel structures acc. to EN 1090-2 Exc 3 (Execution Class 3).

Druckguss Service Deutschland GmbH is processing all steels of the material group 1.1 and 1.2 as well as stainless steels acc. to Z 30.3-5 of the general construction approval of the DIBt.

Read more … The welding certificate has been issued successfully.

Funding certificate handed over by Minister Meyer

On Tuesday 08/07/2014 the Minister of Economic Affairs Schleswig-Holstein Reinhard Meyer paid a visit to our company in Lübeck.

In the scope of the plant visit, the Minister handed over the funding certificate in the amount of 500,000 euros to our managing director Heribert Höhr. Hereby the Federal Land of Schleswig-Holstein supports the expansion of our premises in Lübeck / Schlutup - the construction of an additional hall in which the new 'Universal milling center' will find a home.

Read more … Funding certificate handed over by Minister Meyer

DSD GmbH invests in the future

Druckguss Service Deutschland GmbH is expanding its production capacity by a universal milling center!

maximum processing size: y = 6100 mm; x = 12000 mm; z = 1800-2000 mm

Round table size: 130 t SWL

A part of this investment is the establishment in Lübeck / Schlutup of a 900 m2 new production hall, which includes a 100-ton crane.

The extension secures the DSD-quality standard and offers to keep the well known flexibility regarding handling of spare parts and components in the field of service for die casting machines of all manufacturers.

In addition to that, the possibilities of contract manufacturing will expand especially for ...

New Borewelder-System

Since April, a new "internal circumferential build-up welding process" for mobile applications available. With only one set-up process three operations are possible.

PRE BORING - BUILD-UP WELDING - POST MACHINING

NORTEC

the trade fair for production in the north

Tue 21 to Fri 24 January 2014 in Hamburg

We are in Hall A1 at the stand A1.222. The focus is on the presentation of our capabilities in the field of mechanical manufacturing.