Plant engineering

Revisions

Our motto “Everything under one roof”

Because with a vertical range of manufacture of 97%, we offer competent service for ALL manufacturers and sizes of die casting machines.

Services

Sales DTM & casting cell

Design & layout

Placement & installation

Commissioning & production start-up

Aftersales & service & spare parts

Special machine construction

Whether die casting technology or other industries: We develop special machines exactly according to your requirements. From the initial technical concept to the detailed design to the finished system – our team accompanies you through all project phases. After successful FAT, we take care of installation, commissioning and on-site instruction.

The result: customized machine solutions that work reliably and drive your production forward in a targeted manner.

Pictured here: DSD die casting machine with an electric clamping unit and a hydraulic press-fit unit.

Services

Requirements analysis & concept development

Technical design & construction

Production & assembly

FAT (Factory Acceptance Test)

Placement & installation

Commissioning & production start-up

Aftersales & service & spare parts

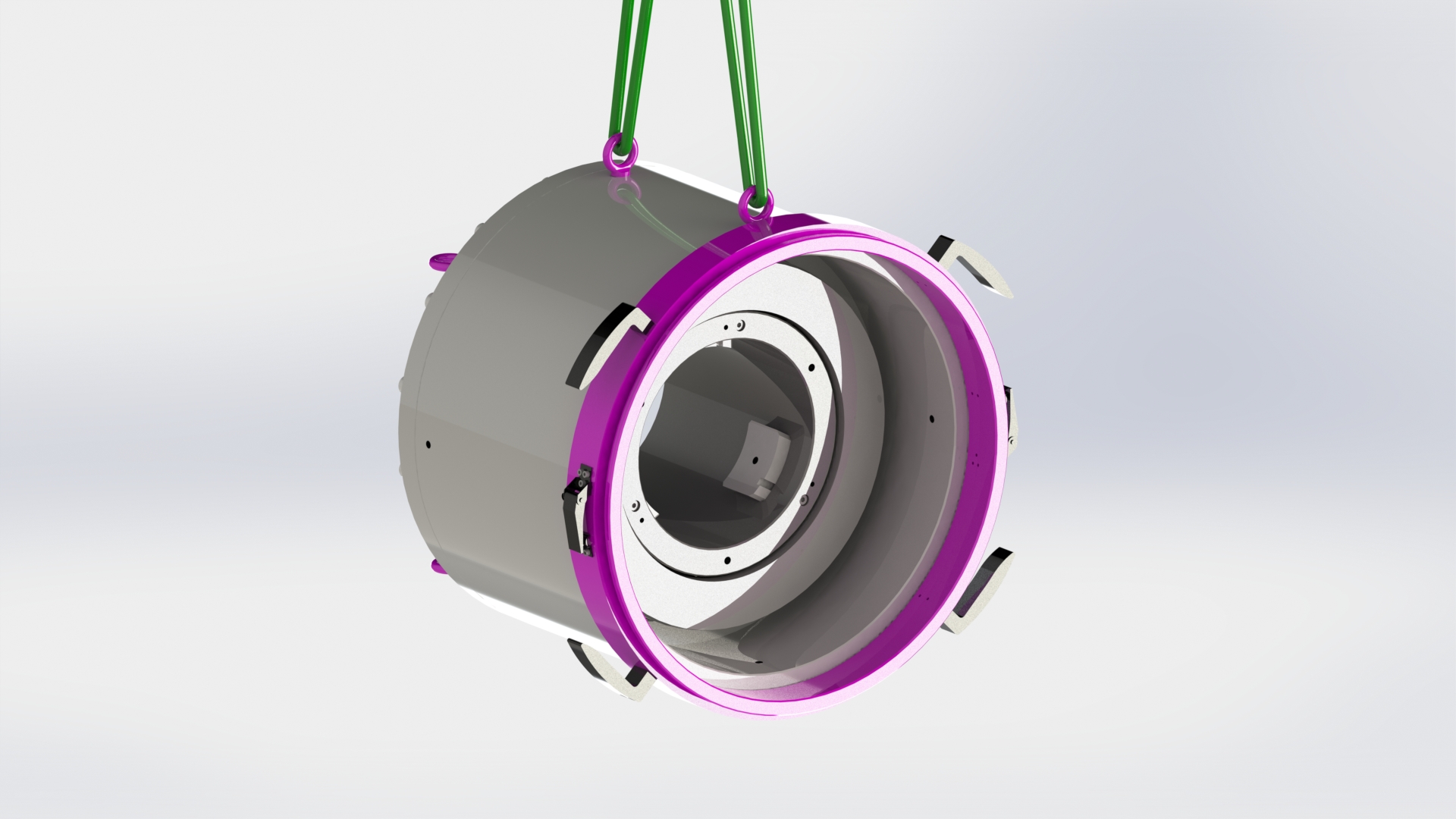

DuoCast

Where experience meets innovation…

DuoCast – innovation in a double pack

Our DuoCast combines a vertical shot unit with a double mould holder – for maximum efficiency with minimum resource consumption.

Thanks to intelligent technologies such as pre-dosing, fast solidification and optimized filling processes, DuoCast offers a wide range of benefits:

🔧 +82 % productivity

🔍 +20 % casting quality

🌍 -71 % CO₂ footprint

💰 -42 % total costs

YIZUMI – LEAP

With clamping forces of 380 to 9000 tons, the LEAP series is ideal for applications in the automotive industry, household appliances, fittings and construction casting as well as for 5G and 3C products.

LEAP stands for:

-

LeadingTechnology – top performance through innovative technology

-

EnergyEfficiency – Sustainable production with reduced energy consumption

-

AdvancedControl – user-friendly control for maximum process reliability

-

Precision– Highest precision and repeat accuracy

Discover the future of die casting with YIZUMI LEAP – efficient, precise and sustainable.

Services

Sales DCM & casting cell

Design & layout

Placement & installation

Commissioning & production start-up

Aftersales & service & spare parts

YIZUMI-THIXOMOLDING

With clamping forces ranging from 650 to 3,200 tons, YIZUMI offers tailor-made solutions for a wide range of requirements. The latest generation, such as the UN1250MGII, enables the production of larger components with an injection volume of up to 2.5 kg.

YIZUMI Thixomolding machines combine the advantages of injection molding with the strength of magnesium alloys and enable the production of complex, lightweight and precise components – ideal for applications in the automotive industry, electronics and medical technology.

Discover the future of magnesium processing with YIZUMI Thixomolding – for lighter, stronger and more environmentally friendly products.

Services

Sales DTM & casting cell

Design & layout

Placement & installation

Commissioning & production start-up

Aftersales & service & spare parts

O.R.C.A – One controller for all!

The O.R.C.A. system – modular, future-proof, manufacturer-independent

With our new ORCA control system, we modernize die casting machines from all manufacturers – regardless of year of manufacture or design. Outdated systems are replaced by a standardized, state-of-the-art control system that offers maximum system availability, intuitive operation and consistent data transparency. IIoT-ready, equipped with OPC UA, MQTT and SQL interfaces, ORCA can be seamlessly connected to MES or cloud systems. Whether energy monitoring or process data analysis – you have full control for efficient, sustainable production.

Highlights

Flexible & independent of age or design

Future-proof – IIoT ready for Industry 4.0 requirements

Increased system availability – fewer breakdowns

Increased efficiency & better CO2 footprint

Transparency through energy monitoring & process data analysis

Strain gauge

Measuring column elongation is revolutionized with our innovative elongation measuring device.

- No time-consuming attachment of strain gauges necessary

- High-precision measurement thanks to special sensor technology

- Non-contact measuring principle

- Wear-free measurement

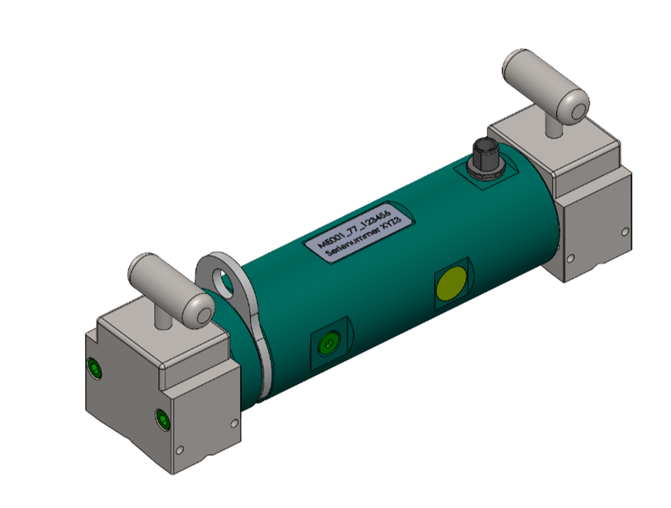

Chamber extractor

The newly developed innovative chamber pulling device solves your problem with jammed filling chambers in chamber holders or molds.

The compact design enables the filling chamber to be clamped, pulled out, stored and transported quickly and safely.

The filling chamber change is optimized, increasing your productivity.

Your advantages through our innovation:

- Filling chamber gentle process

- Effective work facilitation

- Productivity increase

- Accident prevention

- Rapid amortization

- Inexpensive “light” version available

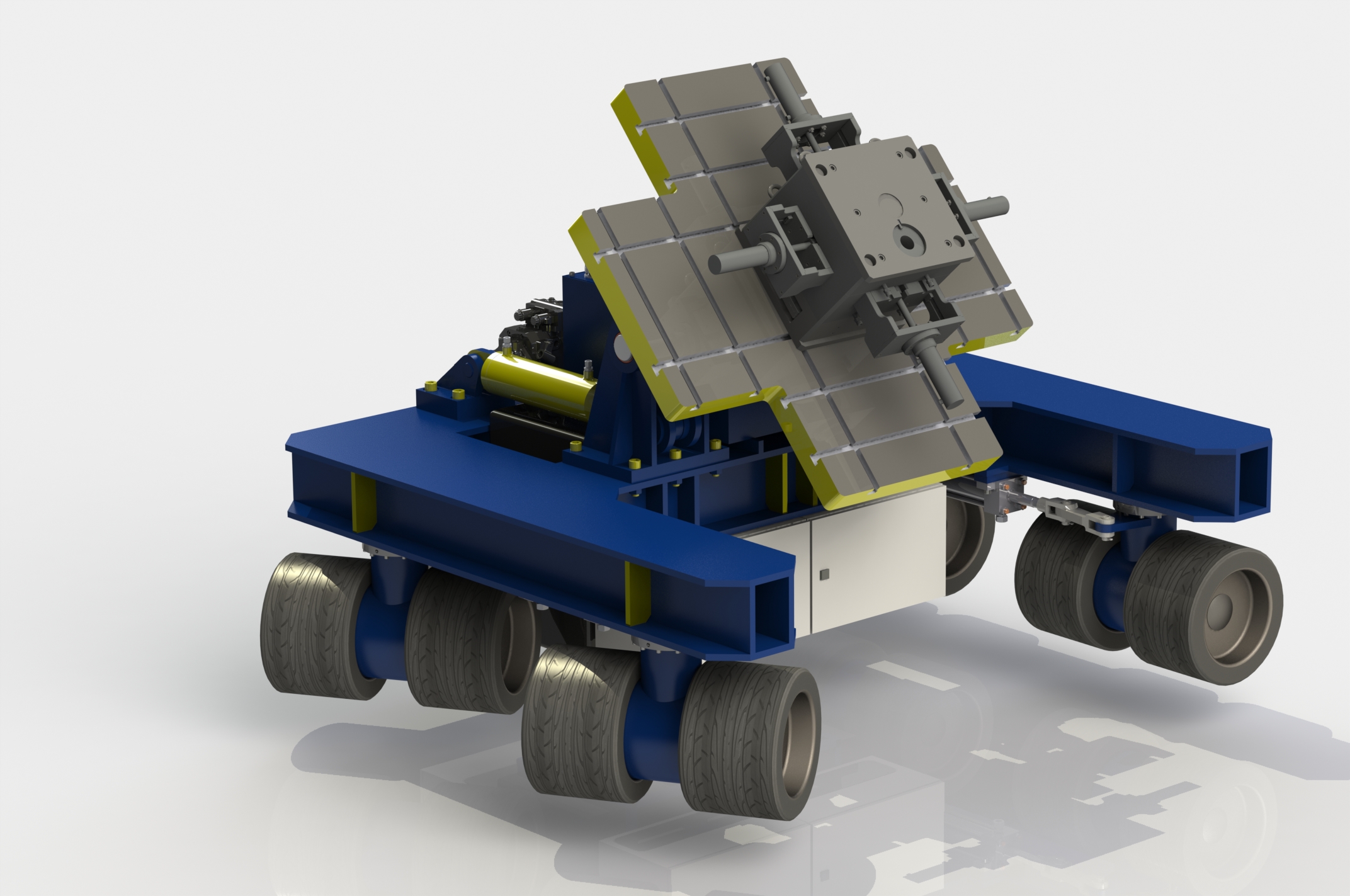

Automatic mold set-up trolley

Stationary or mobile use

Shorter changeover times and increased profitability of your die casting machines.

- Accident prevention

- Effective work facilitation

- Increase in profitability

- Prevention of damage to the die casting mold

- Rapid amortization

The mobile mold trolley is used for vertical pick-up (90°) and for stepless tilting of die-casting molds into the horizontal position. The molds can be worked on comfortably in any position. They can be transported in any position. The key criteria for using the mobile working platform are a significant reduction in changeover time and the resulting increase in profitability.

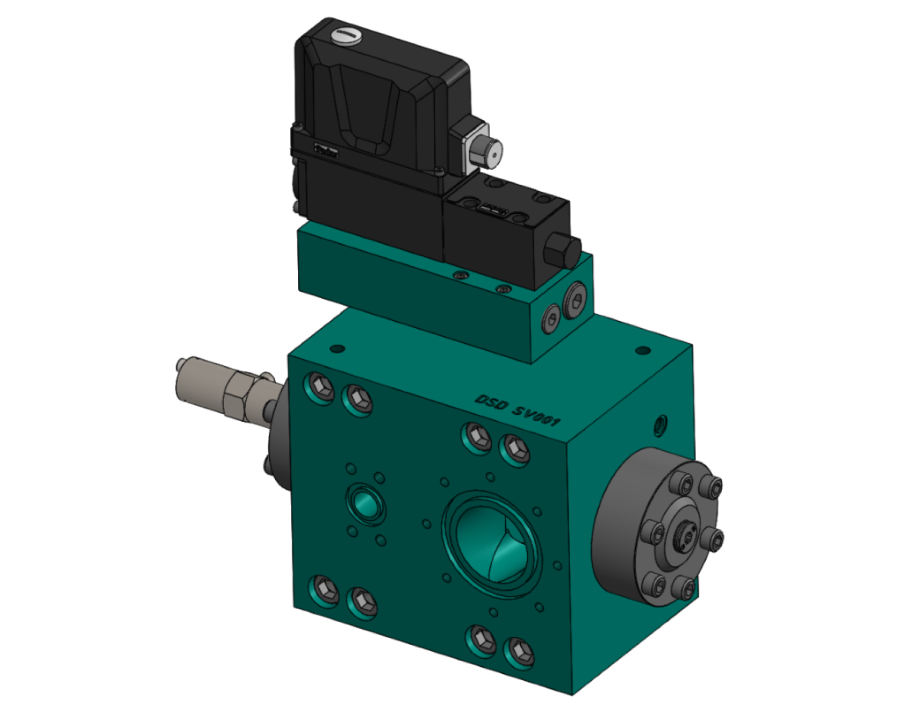

Continuous valve

The innovative DSD continuous valve offers you a cost-effective alternative and can be installed on all Bühler die casting machines in the SC, Evolution and Carat series.

It can be replaced 1:1 without any further conversion work on your machine.

DSD shot

Regulated shot for “old” die casting machines

Combine the solid mechanical engineering of your die casting machine with the latest technology in the shot part. Druckguss Service Deutschland GmbH offers the possibility of shot optimization, produce controlled or conventional. You can simply switch over.

This is basically possible for all machine types!

Energy-efficient

High power density

Longer service life for all interconnected hydraulic components

Increases productivity and saves energy