Metal processing

Precision in every dimension:

With our high-performance machinery, we process complex and large-format components weighing up to 130 tons – including turning, milling, honing, cladding and hardfacing. Whether welded constructions, maritime steel construction or repair welding: we deliver the highest quality from a single source. A special highlight – our mobile processing directly at your site.

Machining

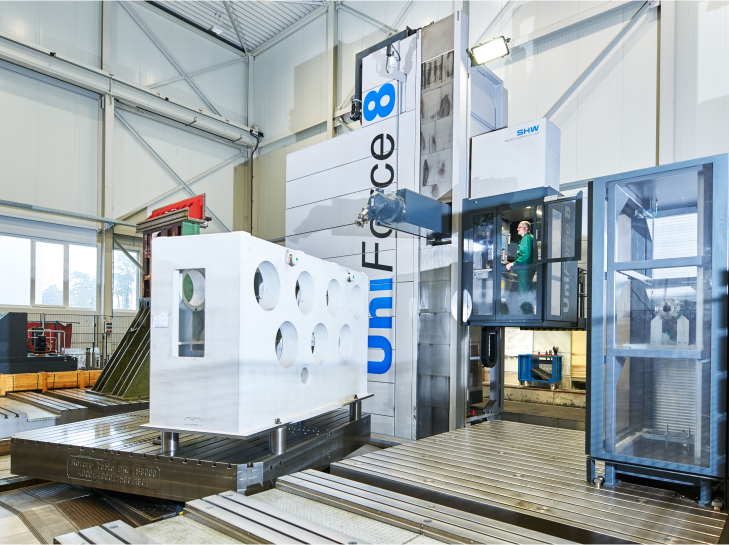

Our company covers a very broad spectrum of machining processes – from the smallest precision parts to large components weighing several tons (up to approx. 130 t ). State-of-the-art CNC lathes and portal milling centers enable high-precision machining of even very large or long workpieces (e.g. shafts up to 12.5 m long). Special processes such as honing extremely long bores (up to 7 m) are also available in order to machine internal surfaces with maximum precision.

Welding technology

Our welding department repairs worn or damaged machine parts by repair welding and protects surfaces by build-up welding (cladding/armoring) with wear-resistant or corrosion-resistant coatings. Innovative high-performance processes such as UP ICE® welding are also used to hardface even large components with minimal heat input. Experienced welding specialists and quality assurance certified to international standards (including ISO 9001) guarantee the highest quality and reliability in all production steps.

Our range of services

up to 130 t unit weight